Laser cleaning is a more precise, safe, and environmentally friendly option than sandblasting . It is ideal for delicate or fragile surfaces, as it does not create any physical contact with the surface, reducing the risk of damage. Laser cleaning produces no harmful by-products, making it a great choice for projects where environmental impact is a concern.

Debating the more cost effective option? Of course, it’s Laser Cleaning!

It is also more precise than sand blasting, making it ideal for removing contaminants from smaller or more intricate surfaces.

1-407-804-1000 ☎

What is DefenseTech?

DefenseTech’s state-of-the-art technology empowers defense industries to maintain equipment integrity and enhance traceability with precision. With our advanced laser marking solutions, you can achieve permanent and high-contrast markings on various materials, enhancing identification and compliance. Our laser cleaning systems effectively remove rust, corrosion, and coatings without damaging underlying surfaces, ensuring prolonged equipment life and operational readiness.

Join us in safeguarding the future of defense technology through innovation, reliability, and unmatched expertise with Laser Photonics DefenseTech.

WITH CLEANTECH

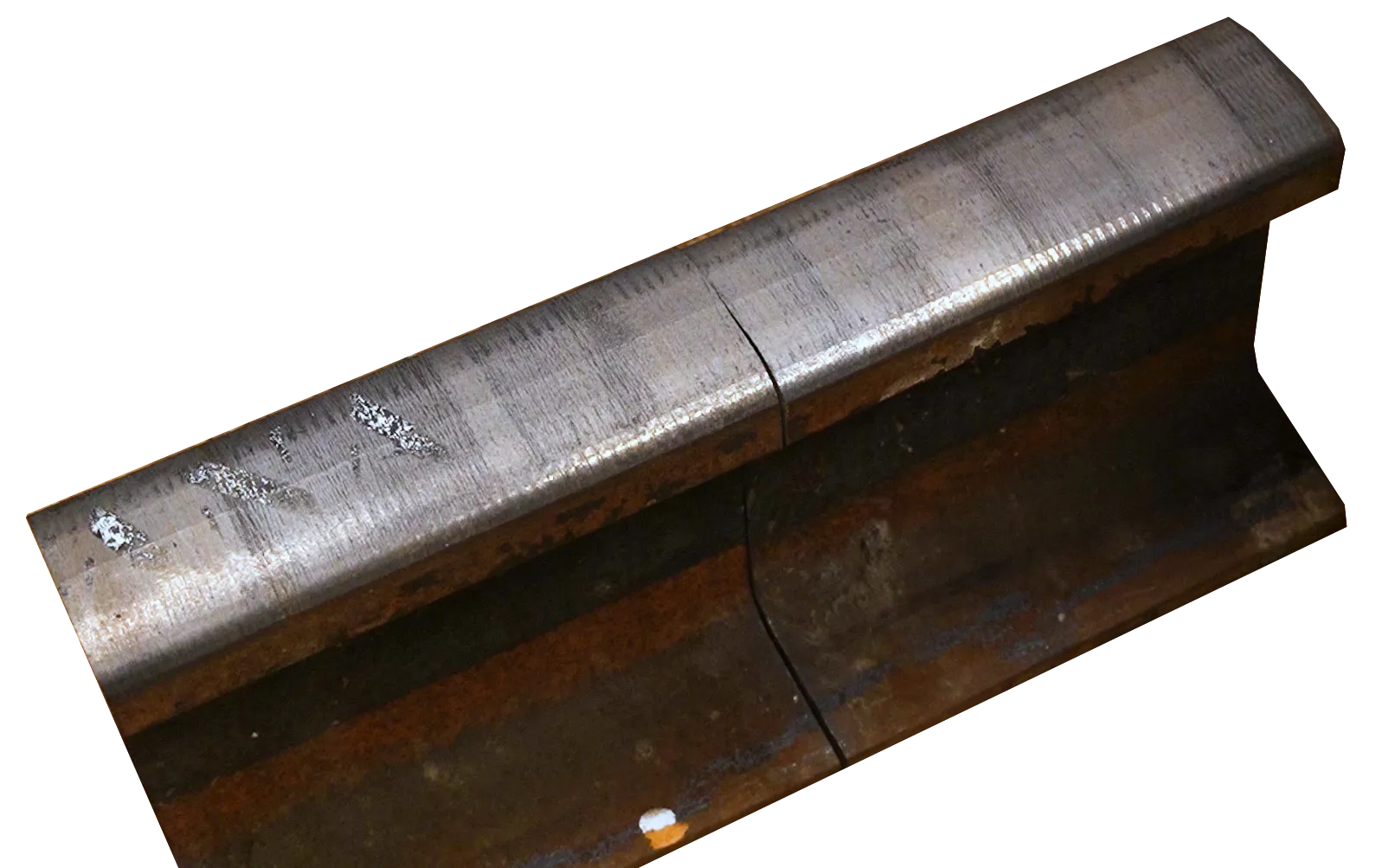

Kill and Prevent

Corrosion

Never worry about rust anymore, we got you!

– Pull the slider to see for yourself –

DefenseTech Solutions for our Military

Laser Cleaning Solutions

In the realm of military-industrial maintenance, traditional cleaning methods like abrasive blasting and chemical treatments bring issues such as environmental pollution, surface damage, and health risks. Laser Photonics’ innovative laser cleaning capabilities encompass the removal of rust, paint, corrosion, and other elements from a variety of surface types, especially in critical sectors such as missile systems, military vehicles, and other essential defense equipment. By adopting DefenseTech lasers, military users can experience a safer and healthier working environment, ensuring their well-being while enhancing overall productivity and efficiency.

Laser Marking Solutions

The US government and Department of Homeland Security have adopted groundbreaking laser programs for Direct Parts Marking, UID, and deep engraving. These processes ensure traceability, production control, inventory management, and product quality. Whether you’re working with missiles, small weapons, ammunition, vehicles, or aircraft and ship parts, this system will deliver results that exceed expectations. DefenseTech lasers maintain their essential role in propelling military-grade laser applications forward within the defense industry by implementing these functions.

Why use Laser Systems over other cleaning and removal methods...

1

Selective, precise stripping of layers.

Laser, unlike sandblasting, is selective, making it easy to focus on a very small spot or strip with no effect on adjacent materials.

2

No damage to the substrate.

The removal of the degraded or coated layer affects only a few microns and the materials absorb the radiation according to their color, making the action of the laser even more specific.

3

Elimination of environmental issues.

Because the laser cleaning system does not require the use of chemicals or of abrasive materials, there are no grinding fumes to breathe or contaminate the area; and no hazardous chemicals to dispose of.

4

Faster, more cost-efficient procedure.

They provide the lowest operating cost of all industrial cleaning methods, are many times faster than the use of chemicals, lowering labor costs, leaves no waste or debris, and often returns on the investment can be seen in less than a year.

This is what you've been looking for!

Choose

Laser Cleaning

over Sandblasting

Mission Ready Laser Solutions For Military Service Branches

A quick look at our DefenseTech products

LPC-MLRI-200

The MLRI-200 is a finishing-class handheld laser cleaning system that provides a non-abrasive cleaning process which is safer, easier to use and more eco-friendly than legacy methods. It minimizes the need for chemicals and pollutants making the technology resistant to environmental and workplace health and safety regulations.

LPC-MLRI-2000

The MLRI-2000 is a handheld laser cleaning machine and surface preparation system designed to remove rust, paint, and other elements from a variety of surface types. DefenseTech cleaning equipment provides a safe and effective solution for all branches of the military to maintain and operate vehicles, aircraft, ships, equipment, and more.

LPC-50-DTBC

The LPC-50-DTBC is a self-contained Class I industrial laser cleaning machine that can be used for parts cleaning, rust removal, and surface conditioning. The Blaster Cabinet can be customized to best fit any application by selecting a power output ranging anywhere from a finishing class fiber laser to a conditioning class fiber laser.

LPC-MS

The LPC-MS is the industry’s first handheld fiber laser marking and engraving system designed for true portability. It is ideal for permanently marking surfaces and for special attention to highly reflective metals. This industrial-grade system was designed to be maintenance-free and to continuously deliver flawless markings on virtually any surface, under any condition.

DefenseTech lasers used throughout the Military...

- Aircraft MRO Cleaning

- Vehicle Maintenance

- Weapon Systems Maintenance & Corrosion Control

- Missile / Munitions Service Marks

- Handheld Service Marks

- Artillery/Munitions Corrosion Control

- UID Barcode

- Parts and Engine Cleaning

- Missile & Torpedo Corrosion Control

- Missile & Torpedo Service Marks

- Pre & Post Weld Cleaning

- Coating Preparation

Schedule a demonstration!

- Laser Finishing

- Laser Cleaning & Surface Prep

- Precise Paint Removal

- Surface Texturing & Conditioning

- Pre-Adhesion Treatment

- Pre- and Post-Weld Preparation

- Degreasing/Decontamination

- Rust & Corrosion Removal

- Mold Release Cleaning

- Zinc, Anodization, Oxide Removal

| • Steel | • Iron |

| • Ceramic | • Aluminum |

| • Brass | • Titanium |

| • Copper | • Concrete |

| • CFRP | • Plastic |

| • Silicon | • Metal Alloys |

| • Cast Iron | • Carbide |

| • Chrome | • Galvanized Metals |

- Eco-friendly

- Safer for the workforce

- Cost effective

- Fast and easy to use

- Budget friendly

- No consumables

- Low to no maintenance required

- High ROI in the long term

- They run forever, literally!

Cage Code: 7EBG2 /

Unique Entity ID: C1TLM1LG6NE5

We offer custom solutions!

Laser Photonics is a customer focused and result oriented company.

We are always looking for the best solution to provide the best quality of service.

Love the technology? Buy the Stock!

Learn more about investment opportunities.

Questions?

- Ask us by web

- 407-804-1000

- defensetech@laserphotonics.com

- Visit Our Store

Search for a page:

© 2023 Laser Photonics