Laser Solutions For All Your Needs

Serving as the #1 Leading Partner of Fortune 1000 Companies in Aerospace, Defence, Energy and Shipbuilding for over 40 years

Our GoalProviding Best Quality Laser Equipment

Safe

Eco-friendly

Easy to use

Cost effective

What Our Machines DoCleaning, Cutting, Marking, Engraving... We do it all!

Laser Cleaning

The most eco-friendly and safe industrial laser cleaning and surface conditioning systems on the market today

Laser Marking

Incredible results under any consition, maintenance-free, no consumables required!

Laser Cutting

For precise cuts with a high-quality finish

Laser Engraving

Designed to outperform any competitors technology

No more safety issuesAbrasive Blasting is too dangerous, save lives with Laser Technologies

Abrasive Blasting Cons:

Laser Cleaning Pros:

Our BrandDifferent from the others, and proud of it

40 years providing for Fortune 1000 companies

Laser Photonics has been recognized as the industry’s #1 brand of industrial-grade laser marking, laser engraving, laser cleaning, and laser cutting machines located in Orlando, Florida. Offering the largest family and product line of standard and specialized laser-based systems, including both Galvo driven and flying optics technologies, Laser Photonics’ commitment to excellence is demonstrated with each new customer experience as our team is part of the process towards optimizing the final system specifications based on the unique requirements of each client application.

Our ServicesOur solutions have been used in various industries for over 40 Years

Aerospace

Soaring Above the Rest: Help Your Business Take Flight with Laser Solutions for Aerospace

Automotive

Driving Precision, Powering Performance: Laser Precision for Automotive Excellence

Military & Defense

Maintaining Combat Readiness: Laser Maintenance Solutions for Military Use

Electrification & Batteries

Electrification and Laser Cleaning: Improving the Performance of Electric Vehicle Batteries

Nuclear & Energy

Radiate Success, Not Contamination: Laser Applications in the Nuclear Industry

Wind, Oil & Gas

Sharper Solutions: Laser Applications That Are Revolutionizing Energy Extraction

Shipbuilding & Maritime

Batten Down the Hatches: Revolutionizing Shipbuilding for Manufacturers

Space Exploration

To Infinity and Beyond: Laser Precision Solutions for the Space Exploration Industry

Customers storiesMeet users ofLaser Photonics systems

Michelle

Michelle has a charter fishing business in Florida and is out on the water all the time. Being she has paying customers on her boat daily, she is fastidious about keeping her boat in “ship shape.” This includes the corrosion that keeps showing up on her railings and anchor chains. She uses the Marlin for spot treatments so she can get ahead of the rust and keep the boats downtime to a minimum.

For Michelle, the Marlin . . .

-

-

- Saves time on boat maintenance,

- Saves money as work can be done by herself,

- Is portable and easy to store,

- Is easy to use and makes fast work of the task,

- Doesn’t require numerous safety equipment,

- Saves on downtime, increasing profits.

-

Peter

Peter owns an auto and truck parts manufacturing company in Miami and wants to be able to efficiently mark parts with part numbers and serial number. Peter chose the MarkStar Pro to ensure traceability of parts and facilitate efficient assembly. Being that laser marking is eco-friendly, permanent, and cost-effective, production has increased.

For Peter, the Markstar . . .

-

-

- Ensures clear and durable markings,

- Improved product traceability,

- Marks endure environmental conditions,

- Is cheap to operate,

- Is environmentally friendly,

- Provides a big ROI,

- Enables seamless part tracking throughout the manufacturing and supply chain.

-

Over 100+ Companies Trust Us

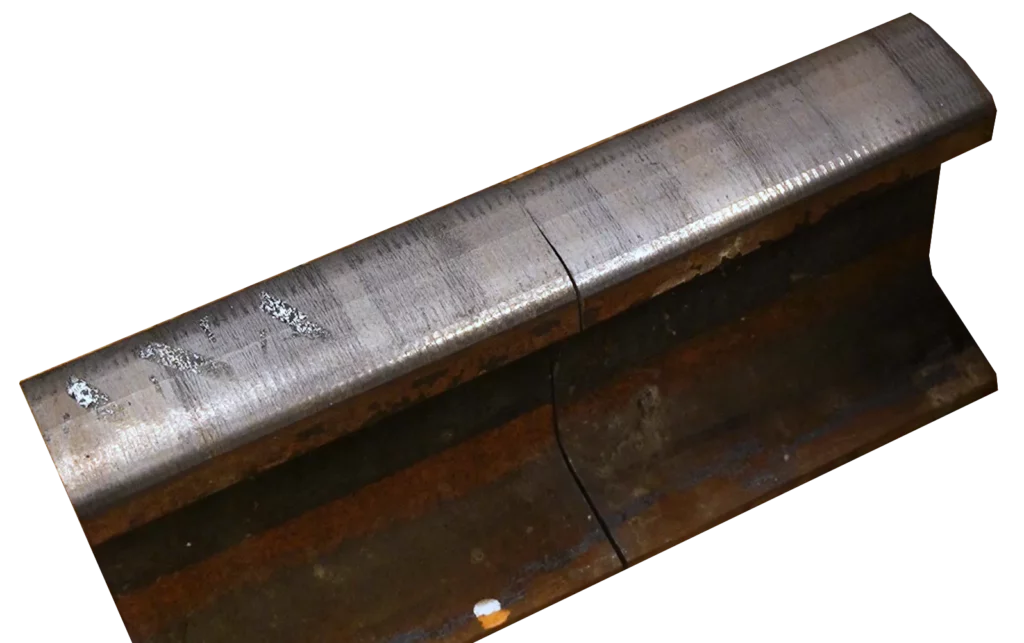

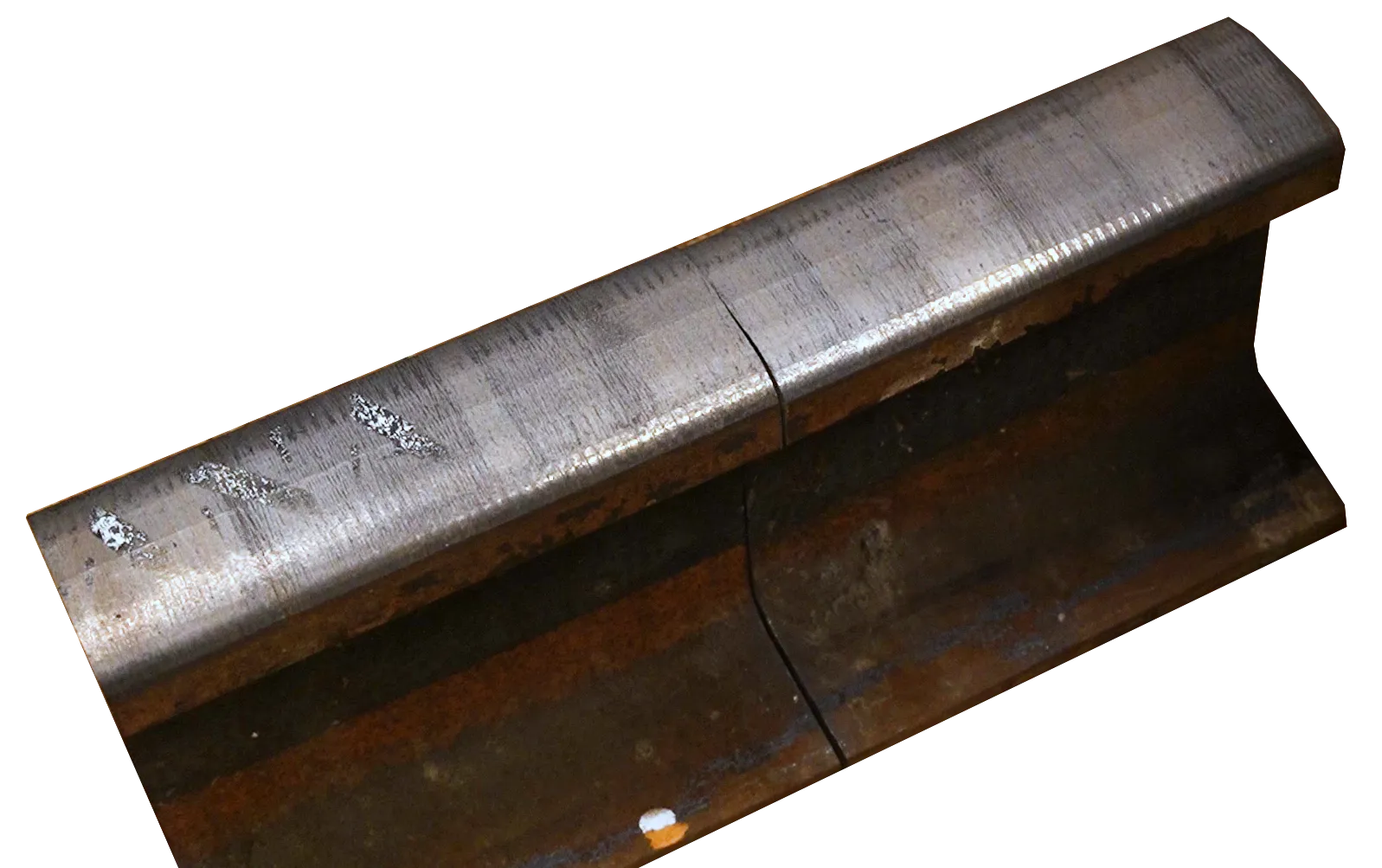

with CleantechKill and Prevent

Corrosion

Never worry about rust anymore, We Got You!

– Pull the slider to see for yourself –

– Pull the slider to see for yourself –

Our Working Process

Send a message

Get In Touch

Get A Quote

Solve Your Problem

HealthAre People Dying To Work For You?

Not. Anymore.

If your business utilizes the processes of sandblasting, dry-ice blasting, bead-blasting, chemical stripping, or mechanical stripping the employees who work in these areas may literally be dying to work for you. There are many long-term health issues that are associated with doing these tasks.

- Abrasive blasting operations can create high levels of dust and noise.

- Abrasive material and the surface being blasted may contain toxic materials (e.g., lead paint, silica).

- Abrasive blasting is known to cause silicosis, a condition where the lung tissue reacts by developing fibrotic nodules and scarring around the trapped silica particles.

So how can you still conduct business while protecting your employees? Consider Laser Blasting, an alternative surface preparation technique that is healthier, cheaper, faster, using a technology that complies with OSHA, EPA and FDA health and environmental regulations.

Why Choose UsEverything you need know

Why partner with Laser Photonics over traditional methods or competing laser machine manufacturers? There are plenty of options available in today’s world, but not all manufacturing and maintenance solutions are created equally. There’s a reason that Laser Photonics is the leading industrial brand for high-tech laser systems:

- Quality: We know that downtime costs money. Every laser machine we manufacture is built and designed to last with minimal maintenance.

- Custom Solutions: We work diligently with our partners to design and create custom solutions to fit perfectly with any business or process.

- Health & Safety: Laser Photonics solutions are eco-friendly, non-toxic, non-abrasive, require no consumables or hefty clean up, and are designed to be compliant with OSHA, EPA, and other regulatory organizations.

Our Sales TeamThe Laser Experts

Vanna Peclet

The Admiral

Seth Bush

The Director

Sunil Singh

The Guy Who Knows How

Rohan Narain

The DefenseTech Guy

TestimonialsRead from 1865 reviews

“We recently tested a Laser Photonics LN120C laser that had sat unused for nearly 20 years. We were delighted to find that the laser operated well despite the long duration in storage. We are planning to use it to test Silicon Photomultipliers (SiPM) for future space experiments.”

NASA

“The laser machine is working perfectly and getting acquainted with the new system. Thanks again for helping us with the process of getting this laser on-line and functional. We will keep a line of communication with you for future reference."

Kel-Tec

“Laser Photonics’ equipment has worked out very well for us, and we have developed a valuable relationship with the company.”

Gables Engineering

Our Latest NewsWelcome to our latest news & recent activity

RELIABLE | EFFICIENT | DURABLE

Let’s build together today!

Stay Laser-Focused,

Subscribe Now!

Illuminate Your Inbox with Laser Photonics Insights.

Subscribe for Brilliance!