"Sharper Solutions: Laser Applications Revolutionizing Energy Extraction"

Lasers in the Wind Industry

Wind power is expected to take an increasingly leading role in the global energy supply. Due to this trend, there is an increasing need to extend the lifespan of wind turbines and to maintain older ones, further increasing the demand for maintenance of these systems.

The wind turbine operation and maintenance market “is expected to grow from $36.27 billion in 2022 to $63.82 billion by 2029, at a CAGR (compound annual growth rate) of 8.4%” (Fortune Business Insights).

Maintenance of corrosion plays an integral role in the operation of wind turbines and the natural electricity they generate. Wind turbines have an average life expectancy of 30+ years and the high-performance coatings on them, at best, have an expected lifespan of 8-10 years.

A reliable solution for coating removal and surface conditioning is essential to maximizing the efficiency of these turbines.

Corrosion can often go unseen and begin to affect the operation of wind turbine towers. This corrosion is typically found in such places as:

-

-

- AC/DC motors & DC generators

- Hydraulic and lubricating systems

- Switchgears

- Control cabinets

- Electrical enclosures

-

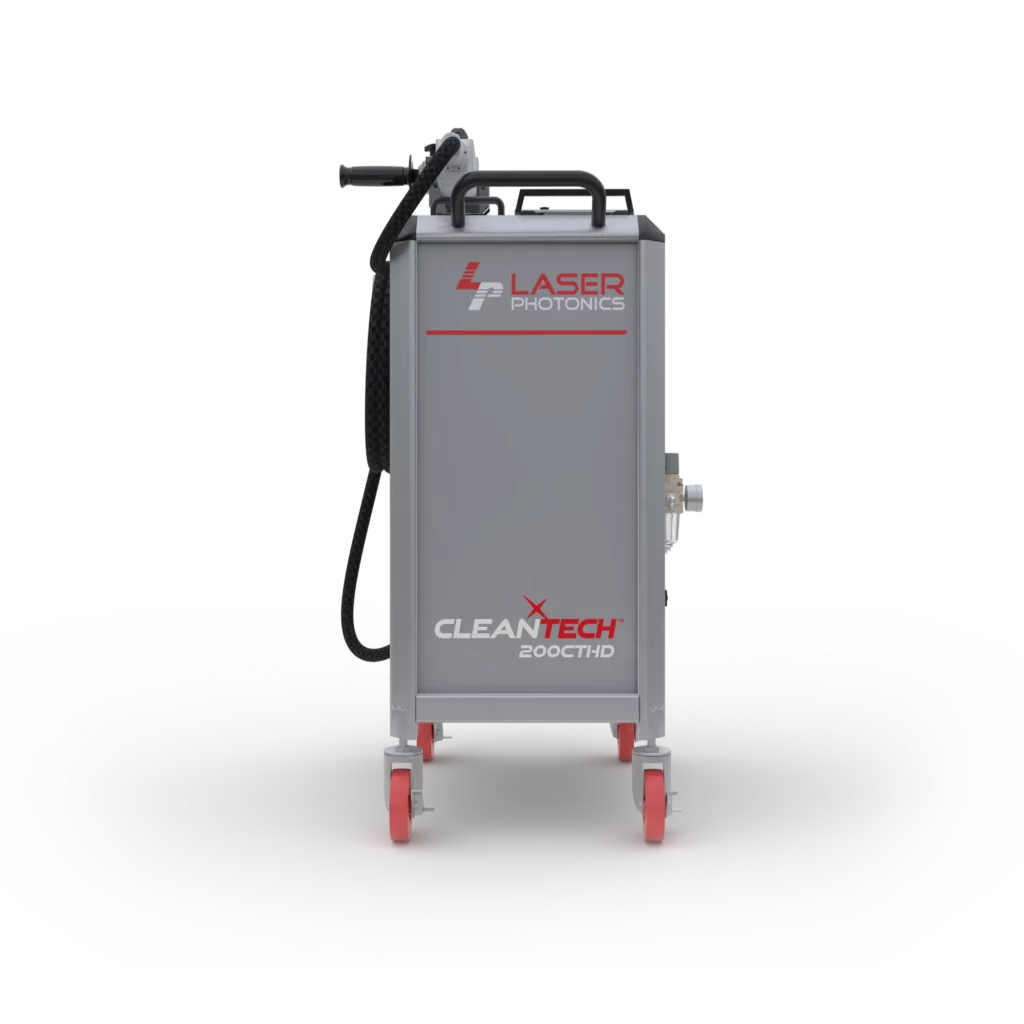

CleanTech™ Laser Cleaning products from Laser Photonics are the perfect solution to mitigate and remove corrosion from wind turbines while remaining eco-friendly, easy to use, and safe to operate by maintenance crews on these large structures.

Lasers in the Oil and Gas industry

Oilfield maintenance of the equipment, structures, and surrounding areas is required to keep the systems safe and in fully operable condition. It is also important to maintain expensive equipment such as drill pipes and elevators. The United States oil and gas pipeline maintenance and repair market “is expected to grow at a CAGR (compound annual growth rate) of 2.4% in the forecast period of 2023-2028 to reach $839.19 billion by 2028” (Expert Market Research).

Both the inner and outer walls of oil and gas pipes develop rust and corrosion over time, restricting their flow capacity and eventually causing the need for complete replacement. Even the slightest decrease in the pipe’s operability and flow can reduce profitability and potentially lead to major downtime for repairs.

Although there are other options for remedying these issues, Laser Cleaning is the best alternative for preventing corrosion damage in the oil and gas industry without the use of dangerous chemicals or abrasive blasting.

Applications in the Oil and Gas Industry:

-

-

- Pre-welding

- Post-welding

- Corrosion removal

- Surface preparation

-

CleanTech™ Laser Cleaning products from Laser Photonics are the perfect solution to mitigate and remove corrosion from oil and gas equipment while remaining eco-friendly, easy to use, and safe to operate by maintenance crews in this industry.

Systems for the Wind, Oil and gas Industries

CleanTech™ LPC-200-CTHD

CleanTech™ LPC-2000-CTHD

MarkStar™ LPC-MS-PRO

We're glad you've decided to learn more about our products!

We offer custom solutions

Laser Photonics is a customer focused and result oriented company.

We are always looking for the best solution to provide the best quality of service!

Ready to place an order?

RELIABLE | EFFICIENT | DURABLE