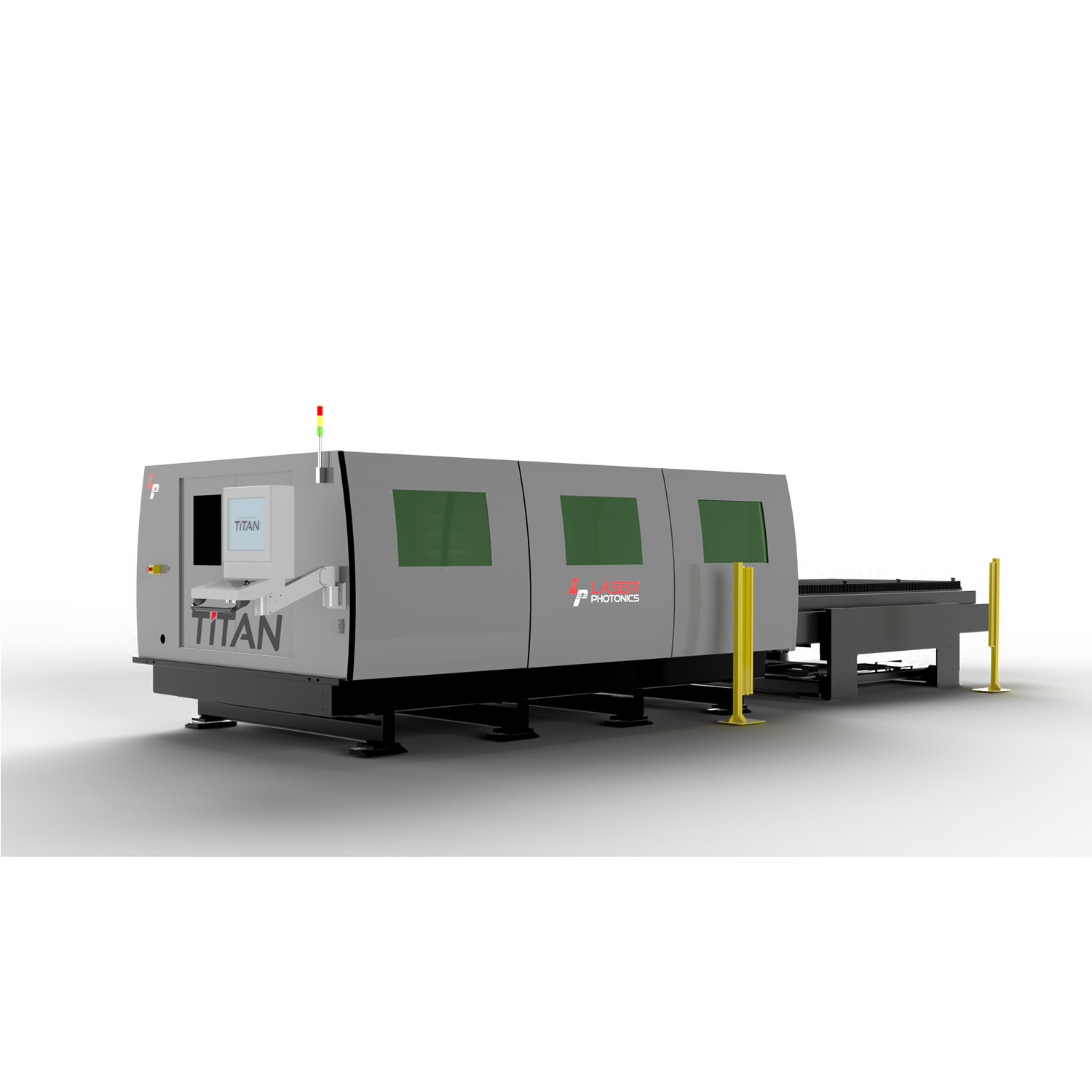

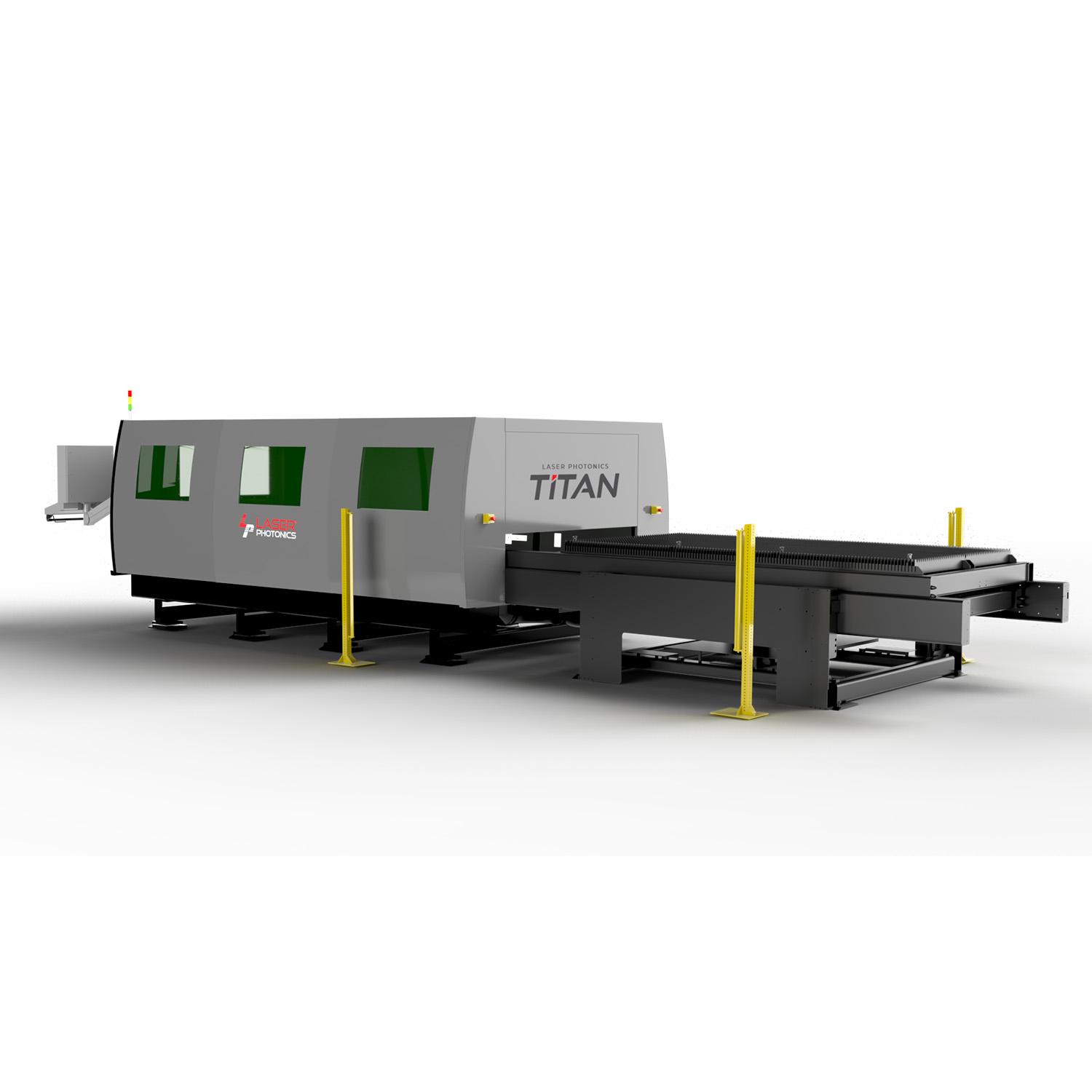

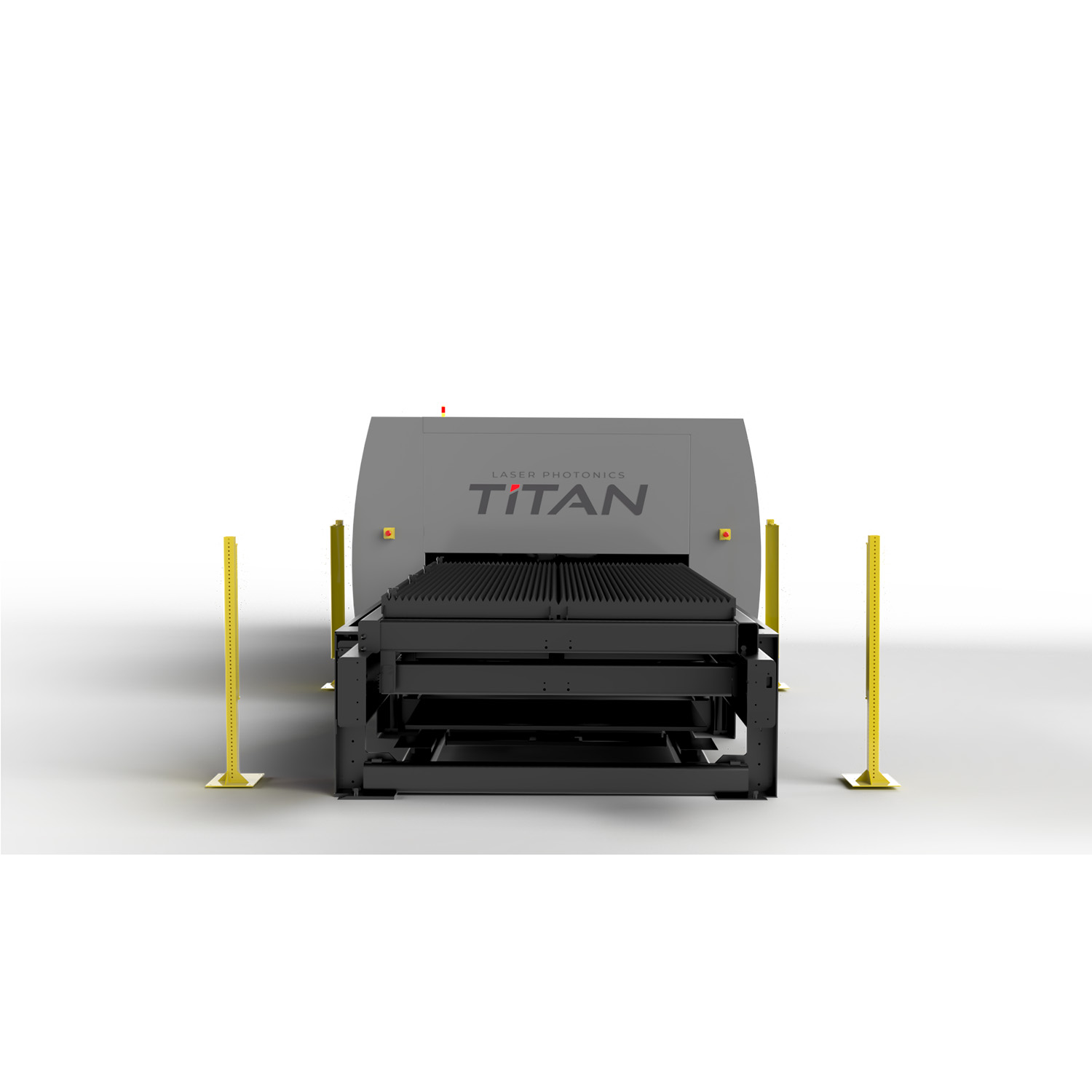

CleanTech™ Titan FX

Overview

The CleanTech Titan Series Laser Cleaning System is a robust solution designed for high-power, large-scale cleaning, rust removal, and surface conditioning of parts. With an impressive working envelope of up to 6′ x 12′, this industrial-grade system can function independently or seamlessly integrate into production lines. Applications span various industries, including automotive (tire rim cleaning), oil and gas (phalange cleaning), and manufacturing (hull sheet cleaning). What sets CleanTech apart is its commitment to a non-abrasive, eco-friendly cleaning process that is both safer and more efficient than conventional methods. The incorporation of proprietary Flexion Technology enables quicker and more thorough cleaning compared to other systems on the market.

Semi-Automatic

Dual-Axis

Roughing

The CleanTech Titan boasts advanced features such as a direct drive motion system, a high-power, low-energy fiber laser, and exceptional industrial reliability with a Mean Time Between Failures (MTBF) of 100,000 hours. The product line extends to include the CleanTech Titan Express, CleanTech Megacenter, and the portable CleanTech Handheld, suitable for both field and factory floor use. Manufactured in the USA, CleanTech Systems adhere to OSHA, FDA, and CDRH standards, ensuring a “Push a Button” laser safety industrial operation. These systems offer a CE Certified Class 1 enclosure for the Class 4 lasers, coupled with an integrated dust and residue collection system. Additionally, CleanTech provides a 3D scanner option for cleaning parts with intricate shapes.

Note:

Please contact our sales engineer before purchasing to ensure you get the right system for your material processing. We’ll discuss your unique needs, customizations, promotions, and schedule a free sample in our lab.

Industries using the Titan FX

Aerospace

- Date Codes

- Serial Number

- Bullet Marking

Automotive

- Paint removal, and surface preparation

- Marking on all automobile parts

- Coating removal on windshields

Military & Defense

- Direct Parts Marking

- UID Marking

- Machine Decontamination

Electrification & Batteries

- Battery Cleaning

- Battery Welding

- Titanium Oxide Removal

Technical Specifications

Applications

| • De-painting | • Cosmetic Surface Conditioning (replaces bead blasting) |

| • Surface and Parts Cleaning | • Selective Paint Removal |

| • Surface Treatment | • Mold Cleaning |

| • Induced Surface Improvement | • Anodizing Removal |

| • Uniform Surface with low HAZ | • 3D Surface Cleaning and Conditioning |

| • High Power Laser Paint Removal | • “On-The-Fly” Laser Cleaning |

| • Subtractive Surface Treatment | • Rust and Corrosion Removal |

| • Surface Texturing | • Degreasing |

Materials

| • Steel | • Iron |

| • Ceramic | • Aluminum |

| • Brass | • Titanium |

| • Copper | • Concrete |

| • CFRP | • Plastic |

| • Silicon | • Metal Alloys |

| • Cast Iron | • Carbide |

| • Chrome | • Galvanized Metals |

System Specifications

Model: LPC Titan FX

Maximum Parts Size Miniature Sub mm to 36” x 36” x 4”

Mode of operation Pulsed Laser

Programmable Z-Axis 4” Travel (for 2D Cleaning Head Only)

Inverted XY System 24” x 24” travel

Cleaning area Standard 26” x 28” with 2D

Cleaning Head Cleaning Area Extended* 36” x 36” with 3D Cleaning Head System

Weight: 375 pounds

Operating Temperature: +18 to +25°C

Relative Humidity: 40 – 80% non-condensing

Electrical Requirements: 120 volt 8 amps Clean Dry Air* (If Required and equipped)** 80 PSI

Process Assist Inert gas Selection*** Nitrogen, Argon, Carbon Dioxide, Compressed air

We're glad you've decided to learn more about our products!

We offer custom solutions

Laser Photonics is a customer focused and result oriented company.

We are always looking for the best solution to provide the best quality of service!