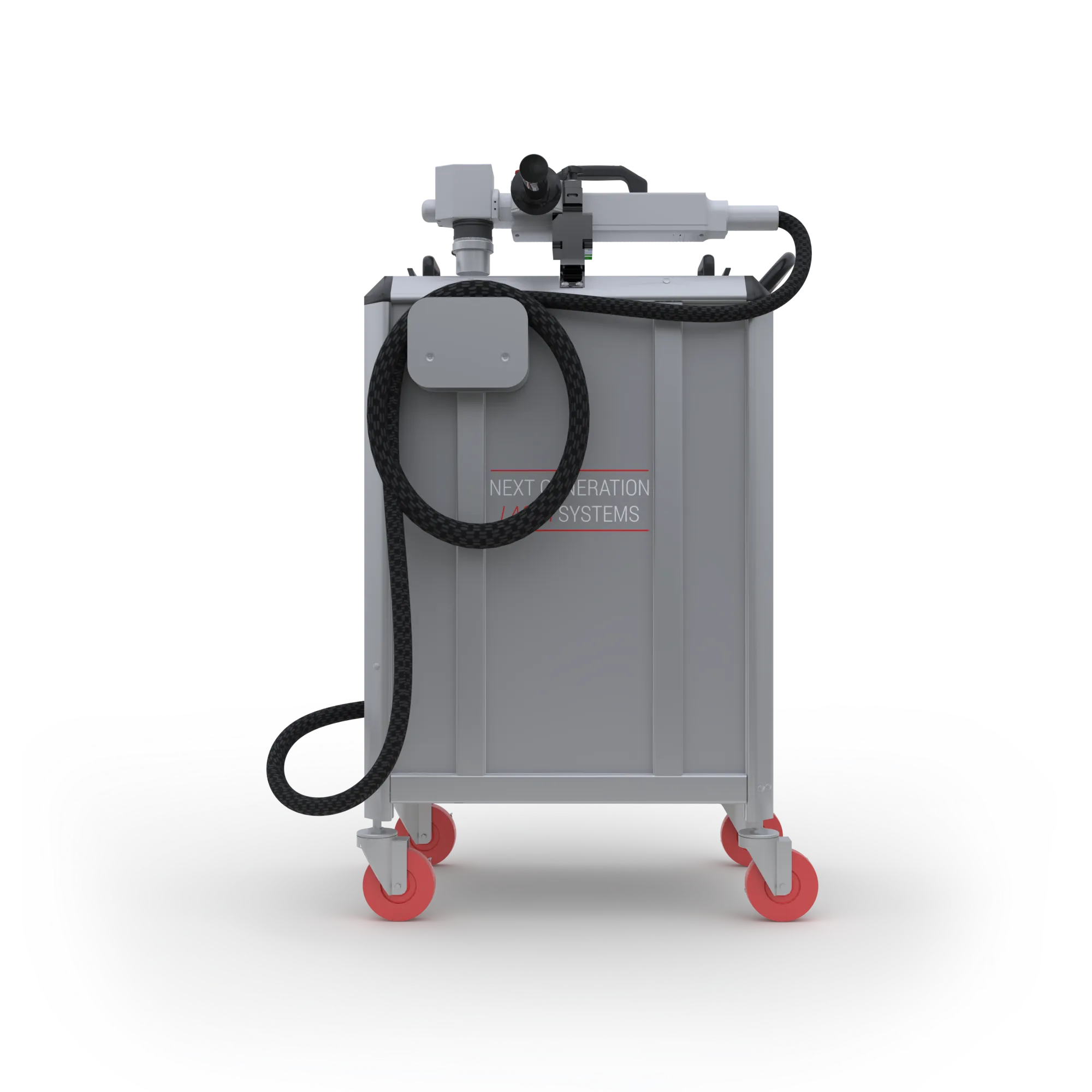

CleanTech™ LPC 300-CTHD

Overview

The CleanTech™ LPC-300-CTHD is a portable handheld conditioning laser that is the perfect tool for laser cleaning and conditioning across a wide variety of surfaces. Complete the job with surgical accuracy, in minimal time, under any condition. The LPC-300-CTHD allows the user to quickly switch from laser cleaning to laser conditioning with the press of a button. You can now clean rust, remove paint and other coatings, then condition the surface of nearly any material- using the same handheld laser. This laser can easily be installed on any production line or robotic arm. The strip rate of the LPC-300-CTHD is 36ft² per hour.

Handheld

Dual-Axis

Conditioning

This portable CleanTech™ system offers a non-abrasive cleaning process that is safer, easy to use and more eco-friendly. It minimizes chemical and abrasive usage in industrial environments to meet increasing compliant demands from OSHA, EPA and other regulatory organizations.

Note:

Please contact our sales engineer before purchasing to ensure you get the right system for your material processing. We’ll discuss your unique needs, customizations, promotions, and schedule a free sample in our lab.

Industries using the LPC 300-CTHD

Aerospace

- Date Codes

- Serial Number

- Bullet Marking

Automotive

- Paint removal, and surface preparation

- Marking on all automobile parts

- Coating removal on windshields

Nuclear

- Marking contaminated tools, parts, and components for Identification

- Coding, Tracking, and identifying

- Cutting metal pipes and structures

Electrification & Batteries

- Battery Cleaning

- Battery Welding

- Titanium Oxide Removal

Technical Specifications

Handheld

A handheld laser system has a head unit that is connected to the main machine via cable, is mobile, and can be used anywhere!

Dual-Axis

A Dual-Axis laser has an optical pattern that is shaped like a box. It will clean the part faster and can handle complex shapes better than a single axis laser.

Conditioning

Conditioning lasers are the best solutions for larger jobs, or smaller projects. Conditioning lasers are between Roughing and Finishing lasers.

Applications

• Laser Finishing, Laser Cleaning & Surface Prep

• Precise Paint Removal

• Surface Texturing & Conditioning

• Pre-Adhesion Treatment

• Pre- and Post-Weld Preparation

• Degreasing/Decontamination

• Rust & Corrosion Removal

• Mold Release Cleaning

• Zinc, Anodization, Oxide Removal

Materials

| • Steel | • Iron |

| • Ceramic | • Aluminum |

| • Brass | • Titanium |

| • Copper | • Concrete |

| • CFRP | • Plastic |

| • Silicon | • Metal Alloys |

| • Cast Iron | • Carbide |

| • Chrome | • Galvanized Metals |

System Specifications

Model Number: LPC-300-CTHD

Strip Rate in ft² Per Hour: 36 ft²

Axis: Dual Axis

Power Output; 300 Watt

Laser Safety Class: Class IV

Wavelength: 1064 nm

Operating Mode: Pulsed

Cable Length: 3-5m

Laser Pattern: 5 Pattern Presets

User Interface: 7” Touch Screen Panel

Operational Voltage: 220v, 60Hz, 15A

Unit Head Weight: 3.6 kg (8lbs)

Operating Temperature: 0-40°C (32°-104°F)

Cooling System: Air Cooling

Safety Features: Emergency Stop, Key Switch, Remote Interlock, Reset & Emission Indication

We're glad you've decided to learn more about our products!

We offer custom solutions

Laser Photonics is a customer focused and result oriented company.

We are always looking for the best solution to provide the best quality of service!