"Smooth Sailing, Crafted with Laser Precision: Innovating Boat Manufacturing"

Pre and Post-Weld Cleaning

Laser Marking for Parts Identification

Lasers have emerged as invaluable tools for parts identification, revolutionizing the production process. With their high precision and speed, lasers are used to mark and engrave crucial information on boat components, ensuring traceability and facilitating efficient assembly.

By employing laser technology, manufacturers can permanently etch serial numbers, part codes, logos, and other crucial identifiers onto various materials, including metal, plastic, and composites. This enables seamless part tracking throughout the manufacturing and supply chain, simplifying inventory management, quality control, and maintenance procedures.

The laser-based parts identification process ensures clear and durable markings that withstand environmental conditions, enhancing reliability and safety.

To summarize, the integration of laser technology in parts identification has streamlined operations, improved product traceability, and elevated the overall efficiency of the boat manufacturing industry.

Display and backlit button manufacturing using lasers

Lasers have emerged as invaluable tools for parts identification, revolutionizing the production process. With their high precision and speed, lasers are used to mark and engrave crucial information on boat components, ensuring traceability and facilitating efficient assembly.

By employing laser technology, manufacturers can permanently etch serial numbers, part codes, logos, and other crucial identifiers onto various materials, including metal, plastic, and composites. This enables seamless part tracking throughout the manufacturing and supply chain, simplifying inventory management, quality control, and maintenance procedures.

The laser-based parts identification process ensures clear and durable markings that withstand environmental conditions, enhancing reliability and safety.

To summarize, the integration of laser technology in parts identification has streamlined operations, improved product traceability, and elevated the overall efficiency of the boat manufacturing industry.

Selective repair of powder-coated parts

Laser technology has revolutionized the boat industry by providing a highly precise and efficient solution for selectively repairing powder-coated components. Powder coating is a popular method for providing a protective and decorative finish to boat components.

However, when these coated parts suffer damage or imperfections, traditional repair methods can be time-consuming and labor-intensive. Laser technology, on the other hand, allows for targeted and controlled removal of damaged or flawed areas without affecting the surrounding coating. By precisely focusing the laser beam, boat manufacturers can remove the damaged powder coating layer and prepare the surface for a seamless repair. The laser selectively ablates the damaged material, leaving the intact coating intact, minimizing the need for extensive reapplication or rework.

This laser-based selective repair process not only saves time and reduces material waste but also ensures a high-quality and aesthetically pleasing finish, thereby increasing the efficiency and sustainability of boat manufacturing.

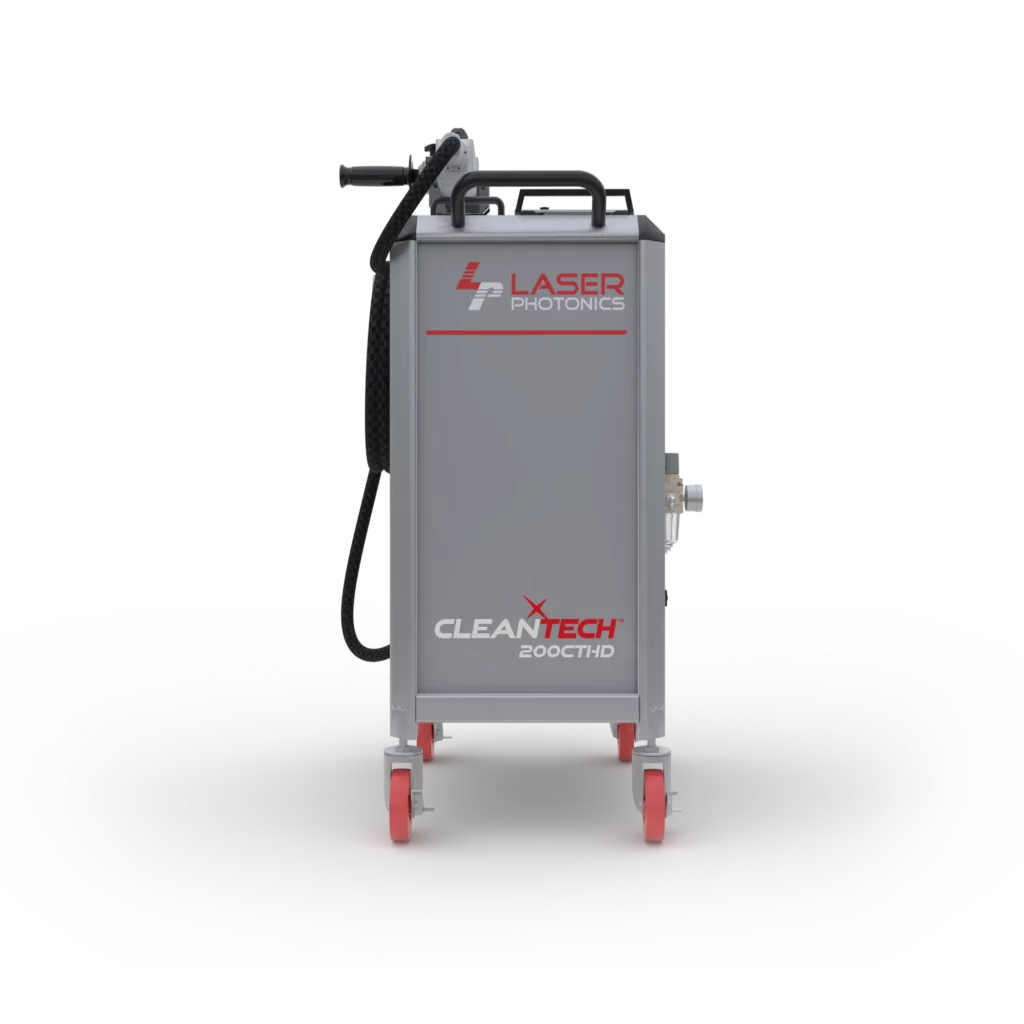

Systems for the Boat Manufacturing Industry

CleanTech™ LPC-50-CTHD

CleanTech™ LPC-100-CTHD

CleanTech™ LPC-200-CTHD

We're glad you've decided to learn more about our products!

We offer custom solutions

Laser Photonics is a customer focused and result oriented company.

We are always looking for the best solution to provide the best quality of service!

Ready to place an order?

RELIABLE | EFFICIENT | DURABLE