"Batten Down the Hatches: Revolutionizing Shipbuilding for Manufacturers"

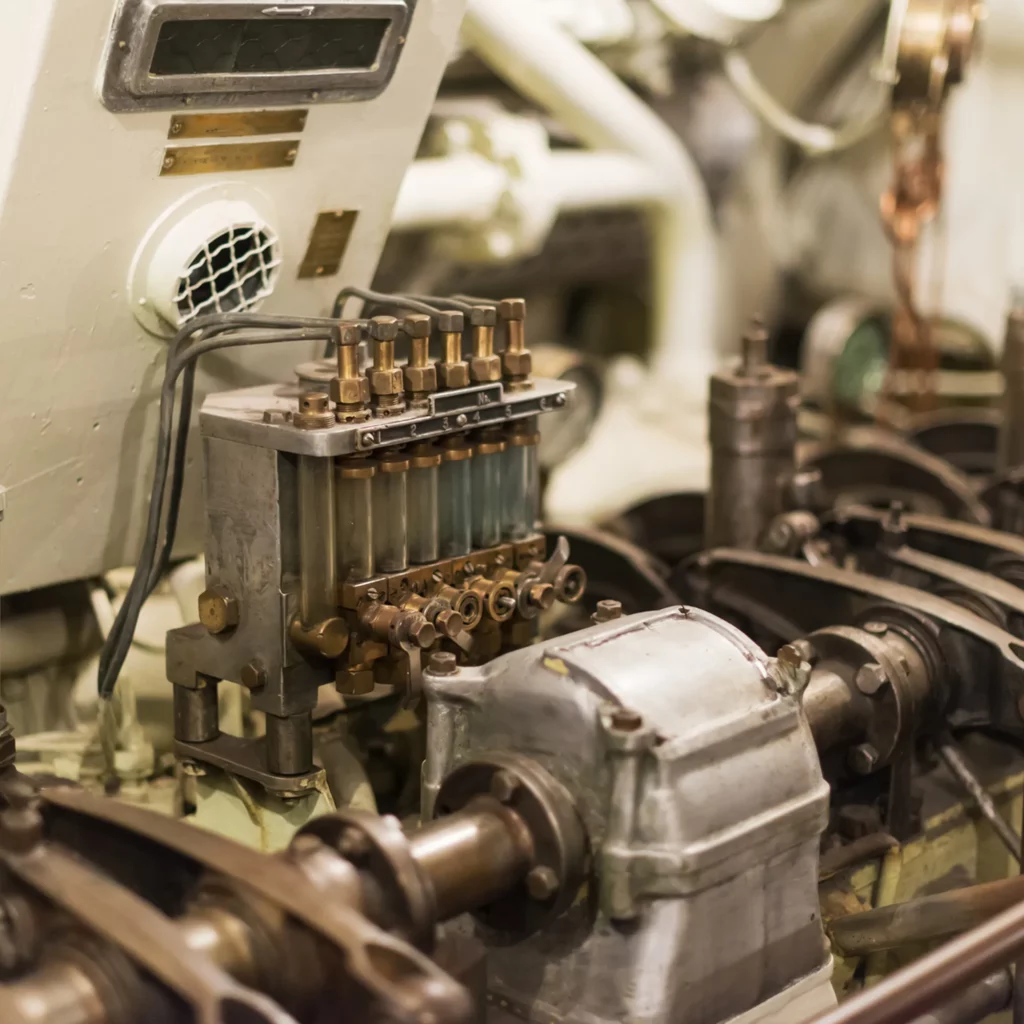

Laser Photonics researches and builds equipment to aid initiatives in the maritime industry, shipbuilding, and ship maintenance/repair processes. We address equipment that has the capability of improving efficiency, safety, inventory management, and more.

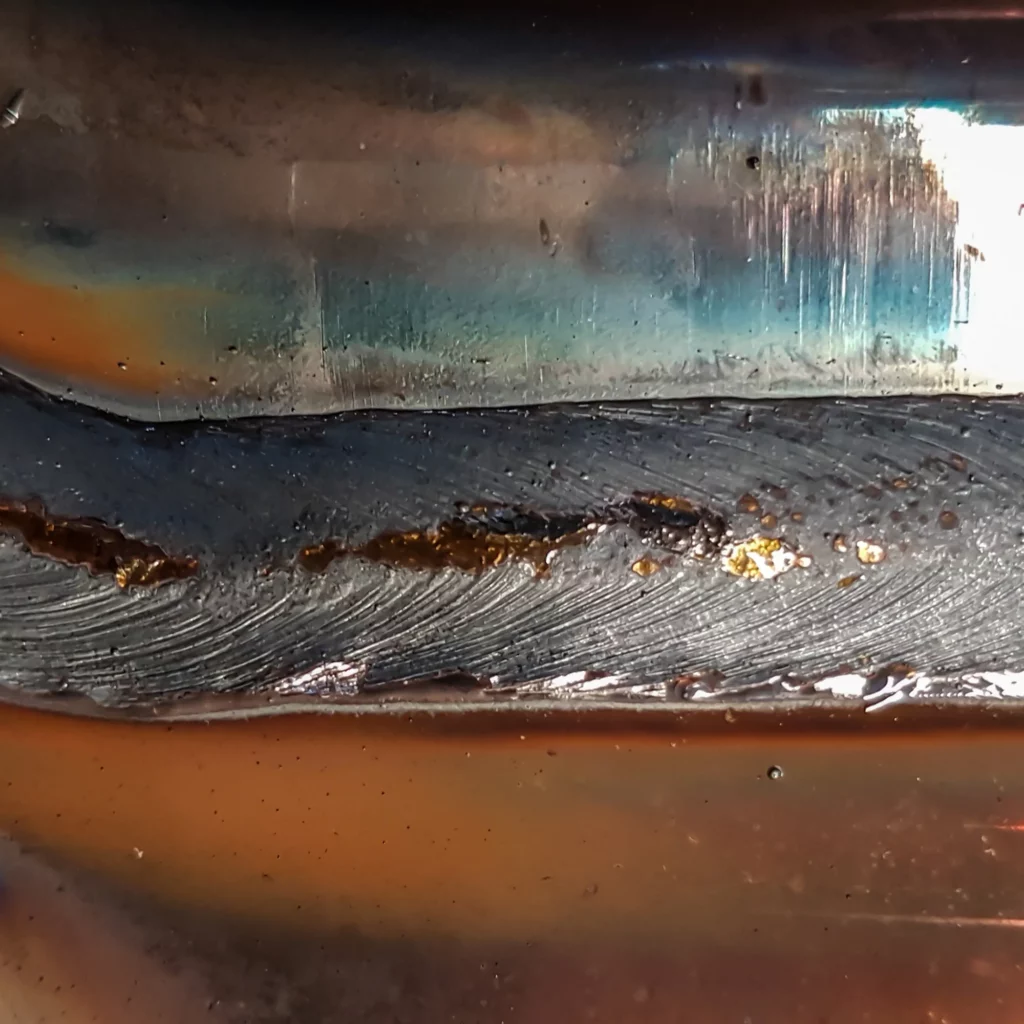

Laser Cleaning in particular is a new disruptive technology effectively replacing environmentally hazardous processes like sandblasting, chemical cleaning, or abrasive blasting – eliminating the health risks associated with sandblasting and chemical cleanings equipment.

Lasers are applicable for contamination removal, surface restoration, surface structure, inventory tracking/management, permanent service and quality marking, and other unique scenarios.

Laser Cleaning and Marking Applications for Shipbuilding

A Safe and Environmentally friendly alternative

By harnessing the power of lasers, we eliminate the health risks associated with conventional cleaning processes. Laser Cleaning offers a safe and environmentally friendly alternative, ensuring the well-being of both workers and the ecosystem. Our lasers excel in various applications, including contamination removal, surface restoration, surface structure enhancement, inventory tracking/management, permanent service and quality marking, and addressing unique scenarios.

Through our research and development efforts, Laser Photonics is at the forefront of advancing the maritime industry, shipbuilding, and ship maintenance/repair processes. Join us on this journey towards cutting-edge technologies that optimize operations, protect the environment, and drive progress.

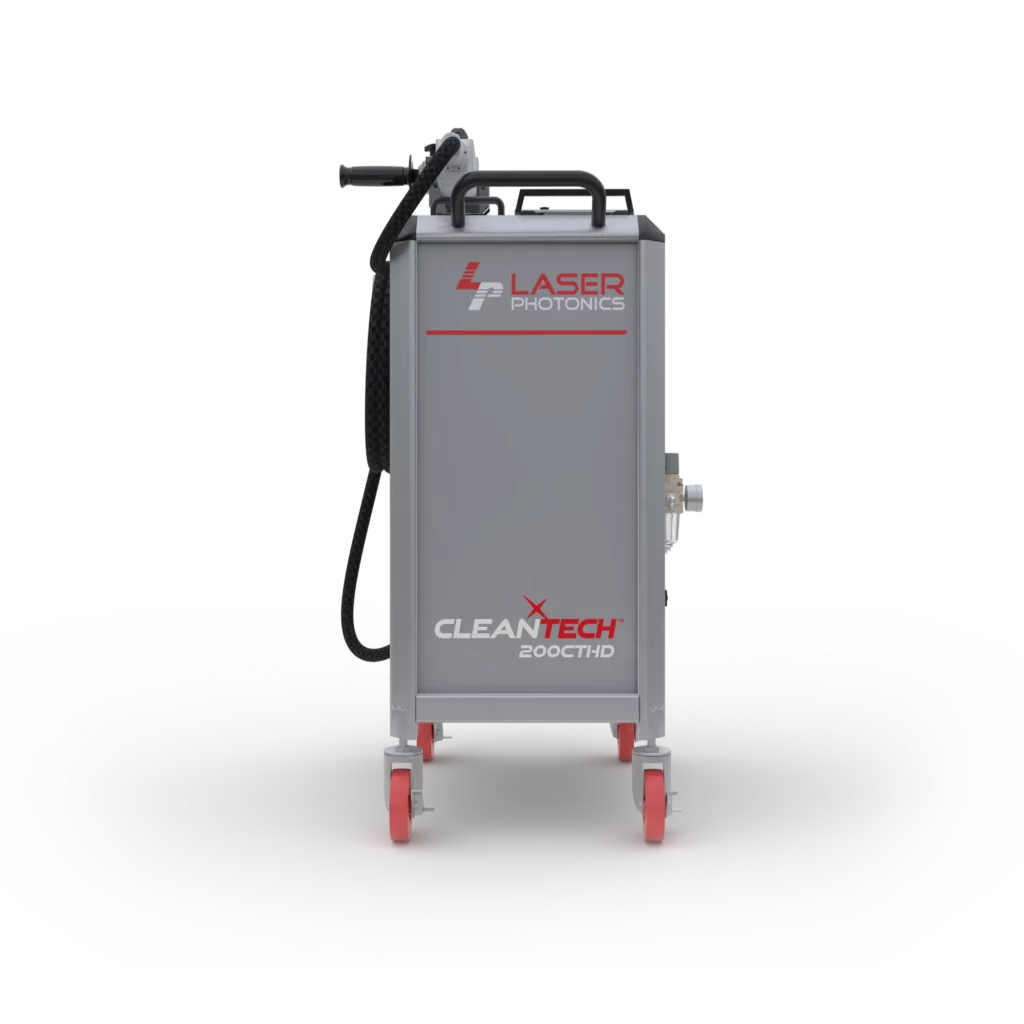

Systems for the Shipbuilding Industry

CleanTech™ LPC-200-CTHD

CleanTech™ LPC-2000-CTHD

Marlin CTH-100M

We're glad you've decided to learn more about our products!

We offer custom solutions

Laser Photonics is a customer focused and result oriented company.

We are always looking for the best solution to provide the best quality of service!

Ready to place an order?

RELIABLE | EFFICIENT | DURABLE